Briquetting Press FOX 60 for woodshavings and other material

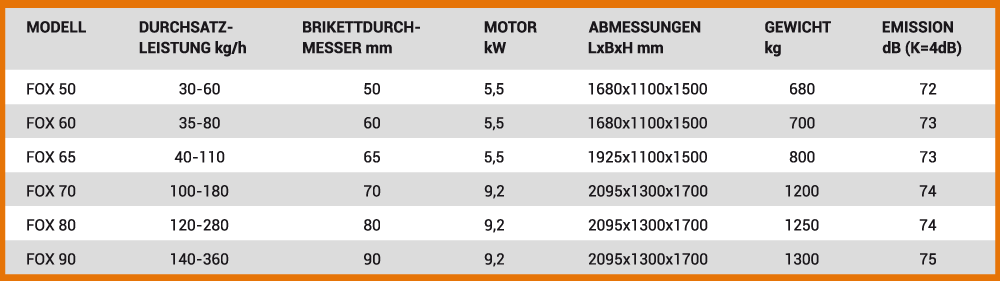

Our FOX 60 briquetting press is produced with a briquette diameter of 60 mm. It is powered by a 5.5 kW motor and achieves a performance between 35 and 80 kg per hour when processing wood chips.

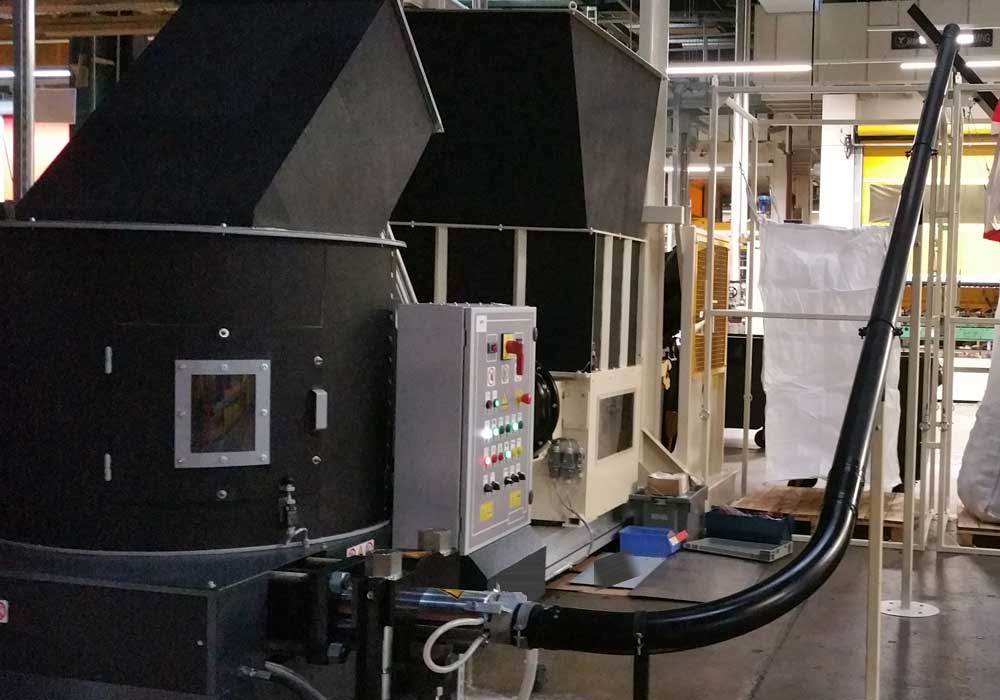

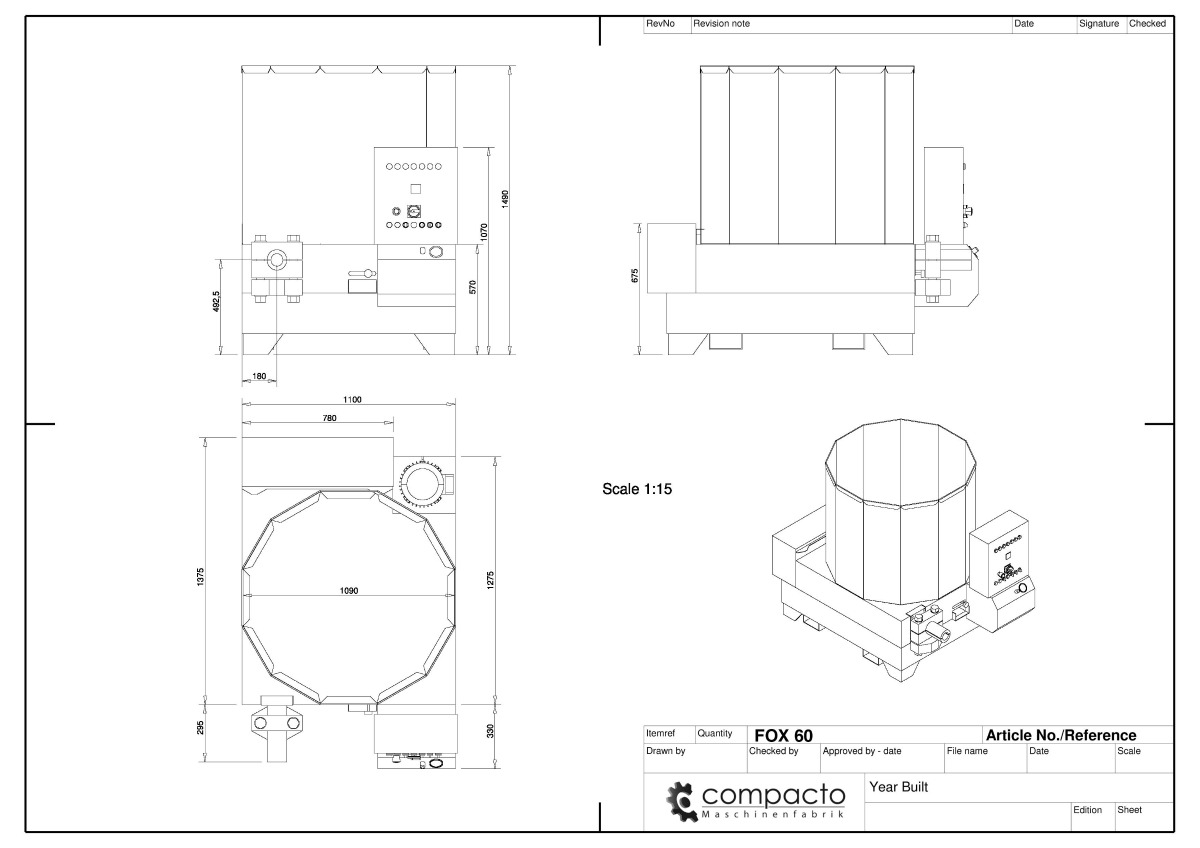

The briquettes are formed and produced in the easy and inexpensive to exchange wear bushings. The front socket of the FOX 60 has a length of 50 mm. In order to keep the wear costs low, the briquettes must not be longer than the wear bushings and therefore the briquette length is maximum 50 mm long. The technical features of our FOX 60 briquetting press is designed according to customer requirements. The feeding process of the material that needs to be pressed takes place by default via a pre-compresser cylinder. The pre-compressor cylinder looks like a drawer. The adjustable opening length of the drawer allows the briquette length to be adjusted. The material supplied through the drawer gives the length of a briquette. The storage container has a capacity of approx. 0.7 qbm and can be delivered in square, round or 12-corner design.

An enlargement of the precompression slide makes sense when processing light materials such as wood shavings, straw or miscanthus. By increasing the size of the precompression slide, it is possible to produce a longer briquette for light materials than what would be possible with the standard cylinder, because more material can be pre-compressed. The length of the briquettes may still be no longer than the length of the wear bushing.

The transport pipe is a component which is screwed on to the crimping pliers. The transport connection can be plugged onto the transport pipe holder. In this way, the briquettes can be transported from the height of the crimping pliers by the power of the subsequent briquette without further energy input, up to a length of about 10 meters, ending up in big bags, containers or the like.

With optional oil cooling, the hydraulic oil is cooled down and the seals in the cylinders are protected against overheating.

An oil heater must be installed if the briquette press is to be operated at temperatures below 4 degrees Celsius. Below 4 degrees Celsius, the oil is too viscous to build up the required pressure. The oil heater keeps the hydraulic oil fluid.

Also possible is the delivery of a special silo, for example, to the substructure under an existing suction or to the wheel loader filling system.

For the briquette packaging we offer a packaging carousel. A total of 5 bags can be filled with briquettes. The weight of the bags is adjustable via the height.

Normally our machines are carefully wrapped with foil before shipping. An elaborate seaworthy packaging for transporting the machines abroad is also possible.

Video: